Brewery Suction & Discharge

Service Temperature Range:

-22°F (-30°C) to +226°F (+108°C)

Branding:

ALFAGOMMA ITALY 422 10 bar (150 psi) BREWERY S&D (brewt logo) – extra flexible – FDA (white letters)

T422LH Series

Liquid S&D Brewery Hose

General Applications:

- Brewery suction and discharge.

- Liquid food and alcoholic beverage suction and discharge, up to 190 proof or 95% alcohol content*.

- Versatile hose for applications requiring superb flexibility and light weight, while still maintaining high strength and durability.

*This correction is to rectify the relationship between the unit proof and % alcohol content in the U.S. system. The alcohol content % = 0.5 x Proof. There are discrepancies between proof and % alcohol content as it differs from country to country. Calculations for the U.S. are shown here. EXAMPLE: Proof is a method of measuring the alcohol content of spirits. A spirits’ product that has a 40% alcohol content by volume is 80 proof [40 multiplied by 2 = 80].

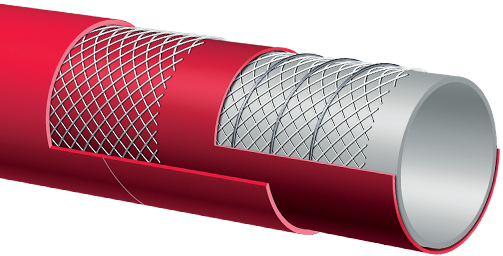

Construction:

- Tube - White Chlorobutyl meeting 3A (18-03) and FDA requirements.

- Reinforcement - High tensile textile cords with specially designed embedded helix wires..

- Cover - Red smooth NR/EPDM blend for abrasion and ozone resistance.

Features and Advantages:

- Extreme Flexibility – Uniquely designed for maximum flexibility, bends easily around brewery equipment and works well in tight spaces.

- Lightweight – Up to 25% lighter weight than similar rubber hoses, while still maintaining 150 PSI working pressure.

- High Heat Resistance - Chlorobutyl tube capable of handling +226°F (+108°C) on a continuous basis. Allows for sterilization with +266°F (+130°C) steam for 30 minutes or with 5% soda solution.

- High Purity Tube - Will not impart odor or taste.

- Smooth Cover – Designed for easy cleaning, no gaps or crevices for dirt or bacteria to hide. Also provides a smooth surface for clamping.

| Nominal Specifications | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Series Number | ID | OD | Max. Rec. WP (PSI) |

Vacuum HG (in) |

Min. Bend Radius at 68°F (in)) |

Standard Length Coils (ft) |

Weight (lbs/ft) |

||

| (in) | (mm) | (in) | (mm) | ||||||

| T422LH100 | 1 | 25 | 1.54 | 39 | 150 | 30 | 2 | 100 | 0.66 |

| T422LH125 | 1 1/4 | 32 | 1.81 | 46 | 150 | 30 | 2 1/2 | 100 | 0.81 |

| T422LH150 | 1 1/2 | 38 | 2.05 | 52 | 150 | 30 | 3 | 100 | 0.93 |

| T422LH200 | 2 | 51 | 2.56 | 65 | 150 | 30 | 4 | 100 | 1.21 |

| T422LH250 | 2 1/2 | 63 | 3.11 | 79 | 150 | 30 | 5 | 100 | 1.81 |

| T422LH300 | 3 | 76 | 3.62 | 92 | 150 | 27 | 6 | 100 | 2.30 |

| T422LH400 | 4 | 102 | 4.64 | 118 | 150 | 27 | 8 | 100 | 3.01 |

CONSULT FOOD HOSE GUIDE IN THE ALFAGOMMA INDUSTRIAL RUBBER HOSES BY KURIYAMA CATALOG FOR MATERIAL COMPATIBILITY ON PAGE 36.